LEGIC Secure Sensor Evaluation Kit

Establishing Trust in the Industrial IoT

Trust in IIoT data relies on linking verified users with trusted sensors and objects so that their interactions are reliable, transparent and accountable.

About the Kit

What is the LEGIC Secure Sensor Evaluation Kit?

Security by Design: LEGIC Trusted Sensors with Secure Element

The LEGIC XDK Secure Sensor Evaluation Kit is the “The Swiss army knife of IoT solutions”. It is a universal programmable sensor device & prototyping platform for any IoT use case you can imagine.

It's a toolkit with state-of-the-art sensor technology and ready-to-use software packages. There is no need for component selection, hardware assembly, or deployment of a real-time operating system, or a development environment.

All the features

What is the LEGIC Secure Sensor Evaluation Kit capable of?

The LEGIC XDK Secure Sensor Evaluation Kit comes with the wireless sensor device XDK110 to enable rapid prototyping of sensor-based products and applications alongside with our LEGIC Extension, which enables security for the internet of things (IoT). It thereby allows users a step in-between the first hardware prototype and series production, or simply as the first compact prototype. Equipped with embedded security module with integrated Secure Element for storage of cryptographic keys/whitelists and wireless communications, it enables rapid prototyping of highly secure, touchless, sensor-based products and applications while offering developers the freedom to rapidly create basic to advanced IIoT solutions.

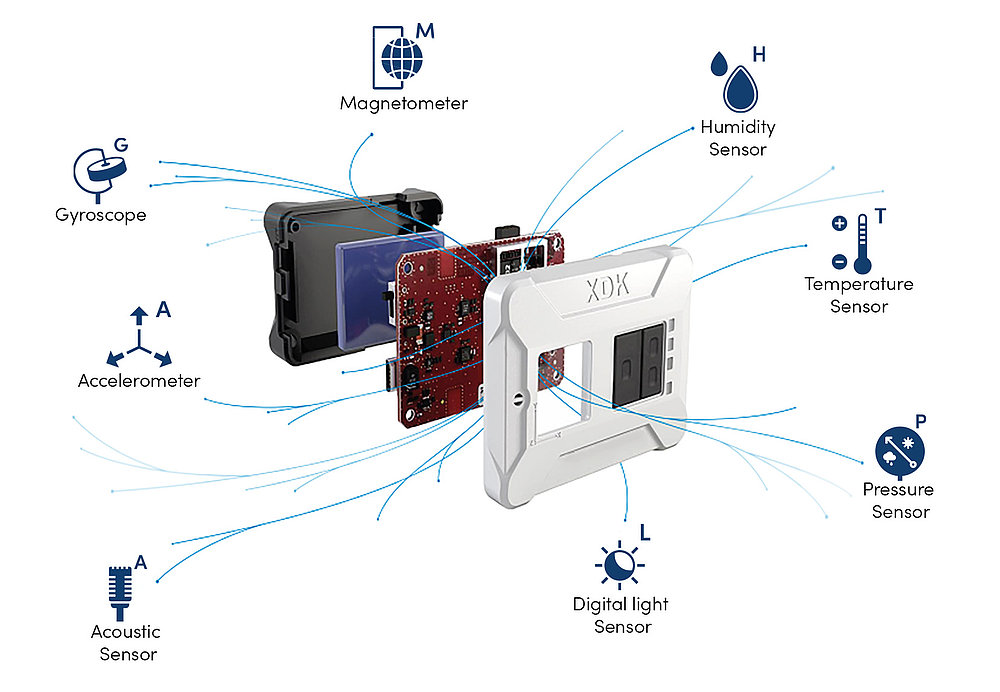

The device includes a full array of Micro-Electromechanical sensors (MEMS). These are the following: Accelerometer, Magnetometer, Gyroscope, Humidity/Temperature/Pressure Sensor, Acoustic Noise Sensor, Digital Light Sensor.

The product dimensions are: 60 mm x 42 mm x 22 mm. Weight: 43g

Download XDK Secure Sensor Kit Flyer Download XDK110 Datasheet

Use Cases

The LEGIC Secure Sensor Evaluation Kit in Action

Predictive Maintenance & Monitoring

Did you ever ask yourself, if the costly maintenance work that is done every single month is actually worth it?

With predictive Maintenance, these thoughts are history. By monitoring and analyzing a machines data, machine or product failure can be predicted with a certain probability. Avoiding those failures allows maintenance teams to invest less resources in maintenance resources. At the same time, maintenance teams are able to increase work productivity as they have more time to focus on vital maintenance tasks.

Benefits:

- Increased asset lifetime

- Increased ROI

- Improved productivity

- Minimize the production hours lost to maintenance

- Minimize the cost of spare parts and supplies

- Improved workplace safety

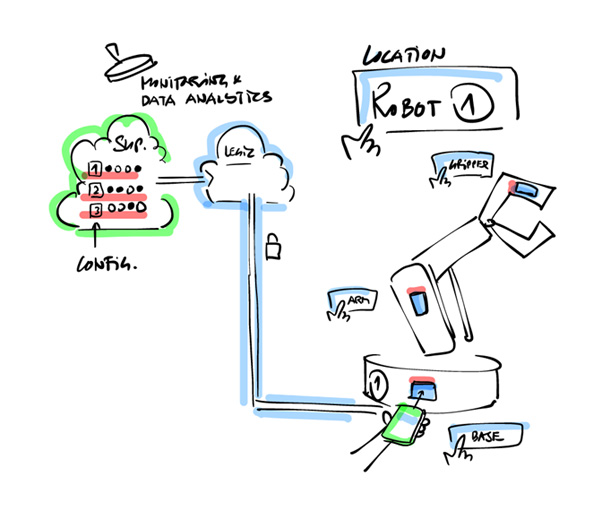

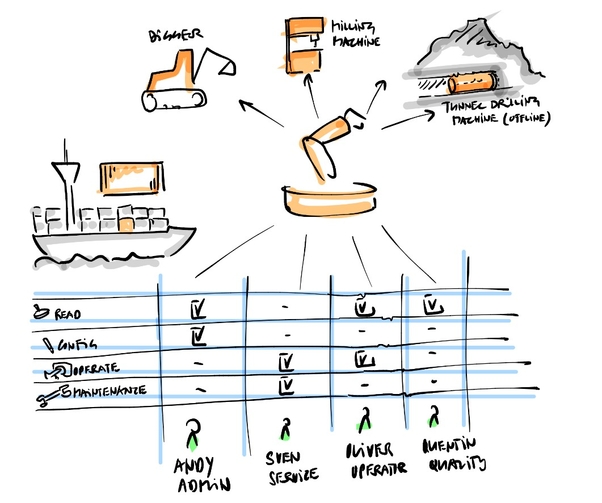

User-Specific Data Access

You need someone to use a dangerous machine to complete a task, but at the same time don’t want unauthorized people to use that machine?

You want to give a specific person access to a machines data to analyze, without giving him the rights to use the machine?

Say no more. With the usage of the LEGIC extension, it is possible to create role-based or user-specific configuration. This ultimately allows you to have control over who is allowed to access what data and who is allowed use what assets.

Benefits:

- Decide who can do what on which assets

- Improved workplace

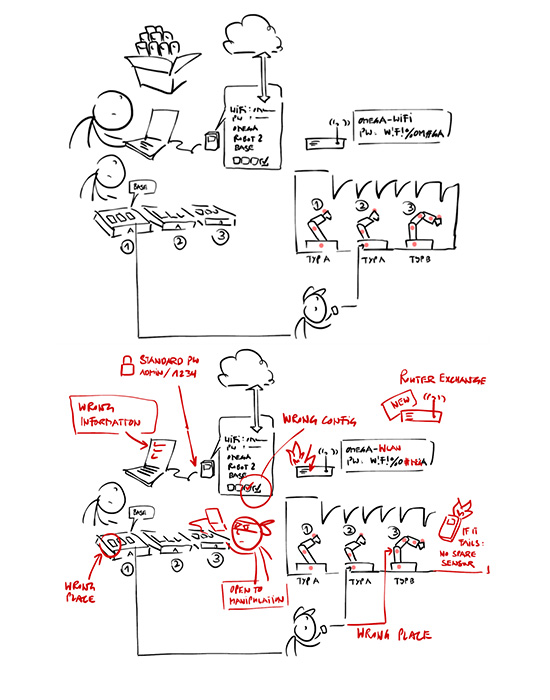

Sensor Configuration & On-Site Commissioning

Why do you need our kit to configure and commission your sensor devices?

The following scenario is still standard in many companies / industries

Bob is responsible for programming all sensors with the individual configurations. To know, which sensor is for what, he packs them in individual packages to keep things tidy. Now John, the on-site worker, must be focused to place all the sensors in the right places, otherwise the use case won’t work.

The state-of-the-art commissioning contains the following sources of error:

- wrong config

- wrong information

- wrong packed

- standard or no encryption

- can be manipulated

- can be incorrectly mounted

- hard to replace at defect

- hard to reconfigure if infrastructure changes

If any of those weaknesses are met, a lot of time and money is wasted, and the work has to be done all over again.

With our kit though, you can randomly place your sensors and commission them for testing purposes with our software solution LEGIC Connect including the LEGIC EKA app. This allows you to create your own configurations in the LEGIC Integration test environment, so that all the sensors can then be commissioned with the newly created configurations.

Partner

Akenza

akenza is the self-service IoT platform, allowing you to build great IoT products and services with value. It connects, controls, and manages IoT devices, all in one place.

With simple and secure management of smart devices, connectivity, and data, the akenza IoT application enablement platform enables the rapid introduction of innovative, smart solutions.

The platform is adapted to organizations of all sizes, from startup to enterprise, from one device to massive IoT deployments. Thanks to the self-service and low-code functionalities of akenza, you can start creating your IoT case right away, even without coding skills.

Get Started

Buy from Us & Project Inquiries

Quick Start Guide

You aldready have your XDK and want to get started?

FAQs

What are the included deliveries?

In addition to the device in its housing, with built-in lithium ion-battery, a break-outboard for easy access to additional MCU functionality, incl. connector and USB cable, a mounting plate and screws, access to the community and to useful documents (getting started guide and data sheet) are also delivered.

What are the dimensions of XDK?

The product dimensions are: 60 mm x 42 mm x 22 mm. Weight: 43g

What hardware interfaces does it have?

The XDK comes with a USB interface to program via boot loader. It also provides a JTAG debug interface for in-depth debugging of the MCU via JTAG debug probe. The extension bus has 23 GPIO pins, including UART, I2C and SPI in addition to 2.5V and 3.3V power pins (power pins limited to 100mA)